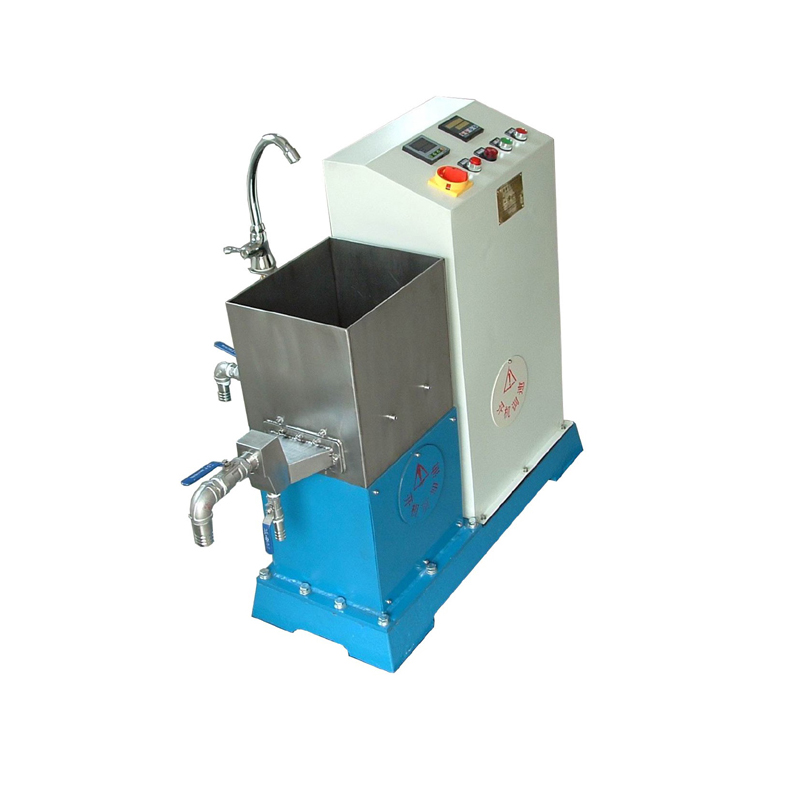

YT-PL27 frequency modulation vibration type rinsing machine is used to simulate the production process of rinsing pulp experiment, which can complete the process of pre-rinsing, rinsing and post-rinsing of pulp.

Structural function: The vibration frequency can be continuously adjusted from low frequency to high frequency, the sieve plate is removable, and different frequencies can be selected according to the slurry.

PL27 frequency-modulated vibrating rinsing machine adopts the speed-regulating reducer to drive the cam through the connecting shaft to vibrate the bottom plate up and down, so that the slurry vibrates at a high frequency, and the generated vacuum accelerates the speed of washing and filtration, and the pulp mass is loosened due to the high-frequency vibration. , In order to speed up the rinsing speed, the rinsing machine is equipped with a 2Kw heater. The vibration frequency of the cam is 0-3000 times/min. The screen machine can obtain higher vibration frequency, and the slurry is evenly dispersed.

● Screening Area:54200mm^2

● Sieve Frame Size:311mmx292mm

● Sieve Specification:80mesh

● Slurry Vibration Frequency:400-3,000 times/min, manual adjustment,digital display

● Slurry Cylinder Size (long×width×high) : 320mm×270mm×300mm

● Rinse Temperature: room temperature 0 ~ 100DEG C continuous adjustable

● Pulp Concentration:4 ~ 8%

● Unique Dried Pulp:0.4~1.13 Kg

● Bleaching Front Wash Time: 5 to 15 minutes

● Fulling Time: 15 ~ 30 minutes

● Bleaching After Washing Time:15 ~ 30minutes

● Motor Power: 750W

● Heating Power: 2KW

● Motor Speed: 200 ~ 1000r/min

Shape Dimension: 360mm×1100mm×880mm

33011002013339号

33011002013339号